Ktajjen tal-Conveyor, inklużi s-Serje M, FV, FVT, MT, ukoll b'Aċċessorji, u Ktajjen tal-Conveyor b'Doppju Pith

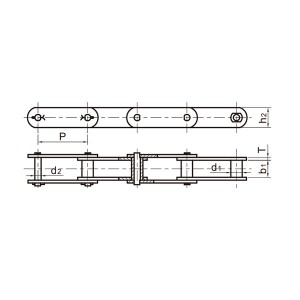

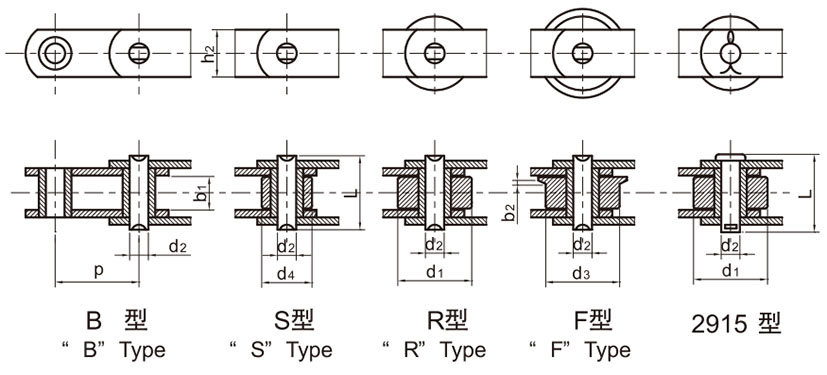

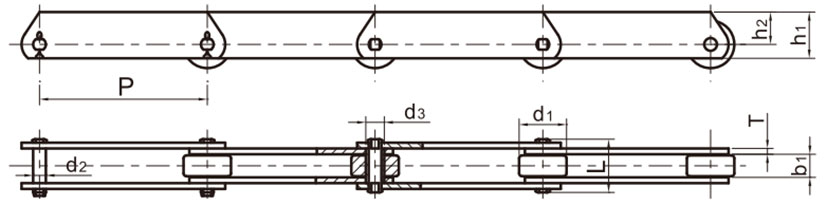

KATINI U ATTACHMENTS TAL-CONVEYOR TAS-SERJE M

| GL Katina Le. | Żift | Dijametru tar-romblu | Wisa' ta' ġewwa | Għoli tal-pjanċa | Dijametru tal-labra | Tul tal-Pin | Saħħa tensjonali aħħarija | ||||||||

| P | d1(massimu) | d3(massimu) | b2(massimu) | d4(massimu) | b1(massimu) | h2(massimu) | d2(massimu) | L | Q | ||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | ||||||

| M20 | 50 | 63 | 80 | 100 | 125 | 160 | 25 | 35 | 3.50 | 12.50 | 15 | 19 | 6.00 | 35 | 20 |

| M28 | 63 | 80 | 100 | 125 | 160 | 200 | 30 | 40 | 4.00 | 15.00 | 17 | 21 | 7.00 | 40 | 28 |

| M40 | 80 | 100 | 125 | 160 | 200 | 250 | 36 | 45 | 4.50 | 18.00 | 19 | 26 | 8.50 | 45 | 40 |

| M56 | 80 | 100 | 125 | 160 | 200 | 250 | 42 | 55 | 5.00 | 21.00 | 23 | 31 | 10.00 | 52 | 56 |

| M80 | 100 | 125 | 160 | 200 | 250 | 315 | 50 | 65 | 6.00 | 25.00 | 27 | 36 | 12.00 | 62 | 80 |

| M112 | 125 | 160 | 200 | 250 | 315 | 400 | 60 | 75 | 7.00 | 30.00 | 31 | 41 | 15.00 | 73 | 112 |

| M160 | 160 | 200 | 250 | 315 | 400 | 500 | 70 | 90 | 8.50 | 36.00 | 36 | 51 | 18.00 | 85 | 160 |

| M224 | 200 | 250 | 315 | 400 | 500 | 630 | 85 | 105 | 10.00 | 42.00 | 42 | 62 | 21.00 | 96 | 224 |

| M315 | 200 | 250 | 315 | 400 | 500 | 630 | 100 | 125 | 12.00 | 50.00 | 47 | 72 | 25.00 | 112 | 315 |

| M450 | 250 | 315 | 400 | 500 | 630 | 800 | 120 | 150 | 14.00 | 60.00 | 55 | 82 | 30.00 | 135 | 450 |

| M630 | 250 | 315 | 400 | 500 | 630 | 800 | 140 | 175 | 16.00 | 70.00 | 65 | 105 | 36.00 | 154 | 630 |

| M900 | 315 | 400 | 500 | 630 | 800 | 1000 | 170 | 210 | 18.00 | 85.00 | 76 | 123 | 44.00 | 180 | 900 |

| 2915-10 | 76.20 | 38.40 | - | - | - | 24.40 | 28.70 | 11.20 | 58.90 | 48.95 | |||||

| 2915-20 | 101.60 | 38.40 | - | - | - | 24.40 | 28.70 | 11.20 | 58.90 | 48.95 | |||||

| 2915-30 | 101.60 | 51.10 | - | 一 | 一 | 27.70 | 31.80 | 11.20 | 63.80 | 62.30 | |||||

| 2915-40 | 101.60 | 38.40 | - | - | - | 21.10 | 31.80 | 12.78 | 64.30 | 71.20 | |||||

| 2915-50 | 101.60 | 57.40 | - | - | - | 32.00 | 38.10 | 15.95 | 90.90 | 106.80 | |||||

| 2915-60 | 152.40 | 51.10 | - | 一 | 一 | 27.40 | 31.80 | 11.20 | 69.10 | 66.75 | |||||

| 2915-70 | 152.40 | 63.80 | - | - | - | 30.50 | 38.10 | 14.38 | 76.70 | 89.00 | |||||

| 2915-80 | 152.40 | 51.10 | - | - | - | 32.00 | 38.10 | 15.95 | 87.60 | 102.35 | |||||

| 2915-90 | 152.40 | 76.50 | — | — | — | 33.83 | 50.80 | 19.13 | 97.80 | 146.85 | |||||

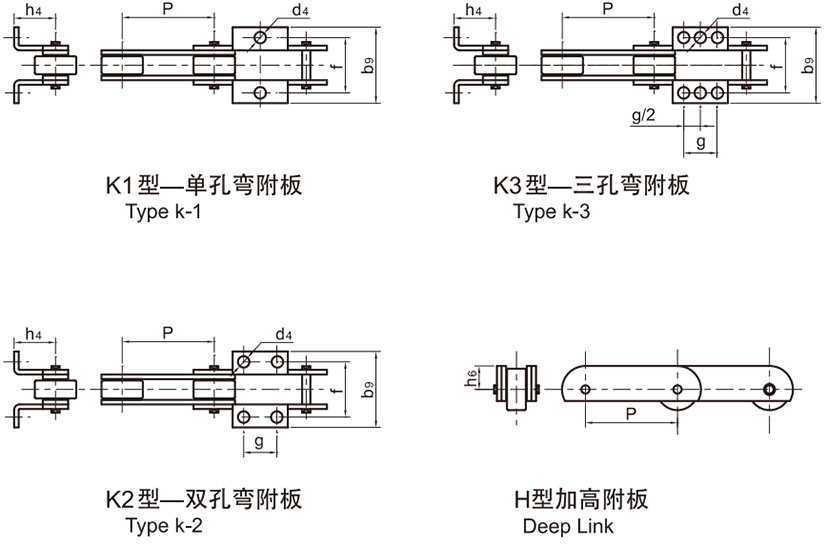

| Katina GL Le. | Tip "K" | Link Profond tat-Tip "H" | |||||||||

| d8 | h4 | f | b9 | 孑L心距 Distanza tat-toqob | H6 | ||||||

| mm | mm | mm | mm | P | g | P | g | P | g | mm | |

| M20 | 6.60 | 16 | 54 | 84 | 63 | 20 | 80 | 35 | 100 | 50 | 16.00 |

| M28 | 9.00 | 20 | 64 | 100 | 80 | 25 | 100 | 40 | 125 | 65 | 20.00 |

| M40 | 9.00 | 25 | 70 | 112 | 80 | 20 | 100 | 40 | 125 | 65 | 22.50 |

| M56 | 11.00 | 30 | 88 | 140 | 100 | 25 | 125 | 50 | 160 | 85 | 30.00 |

| M80 | 11.00 | 35 | 96 | 160 | 125 | 50 | 160 | 85 | 200 | 125 | 32.50 |

| M112 | 14.00 | 40 | 110 | 184 | 125 | 35 | 160 | 65 | 200 | 100 | 40.00 |

| M160 | 14.00 | 45 | 124 | 200 | 160 | 50 | 200 | 85 | 250 | 145 | 45.00 |

| M224 | 18.00 | 55 | 140 | 228 | 200 | 65 | 250 | 125 | 315 | 190 | 60.00 |

| M315 | 18.00 | 65 | 160 | 250 | 200 | 50 | 250 | 100 | 315 | 155 | 65.00 |

| M450 | 18.00 | 75 | 180 | 280 | 225 | 85 | 315 | 155 | 400 | 240 | 80.00 |

| M630 | 24.00 | 90 | 230 | 380 | 315 | 100 | 400 | 190 | 500 | 300 | 90.00 |

| M900 | 30.00 | 110 | 280 | 480 | 315 | 65 | 400 | 155 | 500 | 240 | 120.00 |

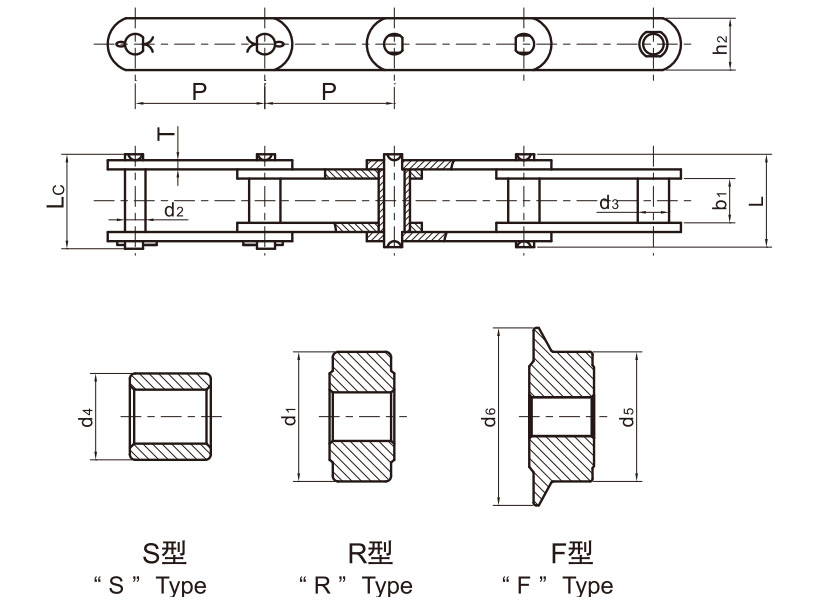

KATINI TAL-CONVEYOR TAS-SERJE FV

| GL Numru tal-Katina | Żift | Wisa' ta' ġewwa | Fond tal-pjanċa | Pin dijametru | Dijametru tal-kanna | Pjanċa Ħxuna | Dimensjoni tar-romblu | Pin Tul | Saħħa tensjonali aħħarija | ||||||||

| P | b1 | h2 | d2 | d3 | T | d4 | d1 | d5 | d6 | L | Lc | Q | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | |||||

| FV40 | 40 | 50 | 63 | 80 | 100 | 18 | 26 | 10 | 15 | 3 | 20 | 32 | 40 | 48 | 37 | 39.50 | 40 |

| FV63 | 63 | 80 | 100 | 125 | 160 | 22 | 30 | 12 | 18 | 4 | 26 | 40 | 50 | 60 | 46 | 50.50 | 63 |

| FV90 | 63 | 100 | 125 | 160 | 200 | 25 | 35 | 14 | 20 | 5 | 30 | 48 | 63 | 73 | 53 | 57.50 | 90 |

| FV112 | 100 | 125 | 160 | 200 | 250 | 30 | 40 | 16 | 22 | 6 | 32 | 55 | 72 | 87 | 63 | 67.50 | 112 |

| FV140 | 100 | 125 | 160 | 200 | 250 | 35 | 45 | 18 | 26 | 6 | 36 | 60 | 80 | 95 | 68 | 74.00 | 140 |

| FV180 | 125 | 160 | 200 | 250 | 315 | 45 | 50 | 20 | 30 | 8 | 42 | 70 | 100 | 120 | 86 | 93.00 | 180 |

| FV250 | 160 | 200 | 250 | 315 | 400 | 55 | 60 | 26 | 36 | 8 | 50 | 80 | 125 | 145 | 98 | 106.00 | 250 |

| FV315 | 160 | 200 | 250 | 315 | 400 | 65 | 70 | 30 | 42 | 10 | 60 | 90 | 140 | 170 | 117 | 125.00 | 315 |

| FV400 | 160 | 200 | 250 | 315 | 400 | 70 | 70 | 32 | 44 | 12 | 60 | 100 | 150 | 185 | 131 | 141.00 | 400 |

| FV500 | 200 | 250 | 315 | 400 | 500 | 80 | 80 | 36 | 50 | 12 | 70 | 110 | 160 | 195 | 141 | 151.00 | 500 |

| FV630 | 200 | 250 | 315 | 400 | 500 | 90 | 100 | 42 | 56 | 12 | 80 | 120 | 170 | 210 | 153 | 163.00 | 630 |

KATINI TAL-CONVEYOR TAS-SERJE FVT/MT

| Katina GL Le. | Żift | Wisa' ta' ġewwa | Dijametru tar-romblu | Dijametru tal-labra | Dijametru tal-kanna | Pjanċa Ħxuna | Fond tal-pjanċa | Tul tal-Pin | Saħħa tensjonali aħħarija | ||||||

| P | b1 | d1 | d2 | d3 | T | hi | h2 | L | Q | ||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | ||||||

| FVT40 | 40 | 63 | 100 | - | - | - | 18 | 32 | 10 | 15 | 3 | 35 | 22 | 37 | 40 |

| FVT63 | 63 | 100 | 125 | 160 | - | - | 2 | 40 | 12 | 18 | 4 | 40 | 25 | 46 | 63 |

| FVT90 | 63 | 100 | 125 | 160 | 200 | 250 | 25 | 48 | 14 | 20 | 5 | 45 | 27.50 | 53 | 90 |

| FVT112 | 100 | 125 | 160 | 200 | 250 | 一 | 30 | 55 | 16 | 22 | 6 | 50 | 30 | 63 | 112 |

| FVT140 | 100 | 125 | 160 | 200 | 250 | 315 | 35 | 60 | 18 | 26 | 6 | 60 | 37.50 | 68 | 140 |

| FVT180 | 125 | 160 | 200 | 250 | 315 | 400 | 45 | 70 | 20 | 30 | 8 | 70 | 45 | 86 | 180 |

| FVT250 | 125 | 160 | 200 | 250 | 315 | 400 | 55 | 80 | 26 | 36 | 8 | 80 | 50 | 98 | 250 |

| FVT315 | 160 | 200 | 250 | 315 | 400 | - | 65 | 90 | 30 | 42 | 10 | 90 | 55 | 117 | 315 |

| FVT400 | 160 | 200 | 250 | 315 | 400 | - | 70 | 100 | 32 | 44 | 12 | 90 | 55 | 131 | 400 |

| FVT500 | 160 | 200 | 250 | 315 | 400 | 500 | 80 | 110 | 36 | 50 | 12 | 100 | 60 | 141 | 500 |

| FVT630 | 200 | 250 | 315 | 400 | 500 | - | 90 | 120 | 42 | 56 | 12 | 120 | 70 | 153 | 630 |

KATINI TAL-CONVEYOR TAS-SERJE MT

| Katina GL Le. | Żift | Wisa' ta' ġewwa | Dijametru tar-romblu | Pin dijametru | Dijametru tal-kanna | Pjanċa Ħxuna | Fond tal-pjanċa | Pin Tul | Tensjoni aħħarija saħħa | |||||

| P | b1 | d1 | d2 | d3 | T | hi | h2 | L | Q | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | |||||

| MT20 | 40 | 50 | 63 | 80 | 100 | 16 | 25 | 6 | 9 | 2.50 | 25 | 16 | 35 | 20 |

| MT28 | 50 | 63 | 80 | 100 | 125 | 18 | 30 | 7 | 10 | 3 | 30 | 20 | 40 | 28 |

| MT40 | 63 | 80 | 100 | 125 | 160 | 20 | 36 | 8.50 | 12.50 | 3.50 | 35 | 22.50 | 45 | 40 |

| MT56 | 63 | 80 | 100 | 125 | 160 | 24 | 42 | 10 | 15 | 4 | 45 | 30 | 52 | 56 |

| MT80 | 80 | 100 | 125 | 160 | 200 | 28 | 50 | 12 | 18 | 5 | 50 | 32.50 | 62 | 80 |

| MT112 | 80 | 100 | 125 | 160 | 200 | 32 | 60 | 15 | 21 | 6 | 60 | 40 | 73 | 112 |

| MT160 | 100 | 125 | 160 | 200 | 250 | 37 | 70 | 18 | 25 | 7 | 70 | 45 | 85 | 160 |

| MT224 | 125 | 160 | 200 | 250 | 315 | 43 | 85 | 21 | 30 | 8 | 90 | 60 | 98 | 224 |

| MT315 | 160 | 200 | 250 | 315 | 400 | 48 | 100 | 25 | 36 | 10 | 100 | 65 | 112 | 315 |

| MT450 | 200 | 250 | 315 | 400 | 500 | 56 | 120 | 30 | 42 | 12 | 120 | 80 | 135 | 450 |

| MT630 | - | 250 | 315 | 400 | 500 | 66 | 140 | 36 | 50 | 14 | 140 | 90 | 154 | 630 |

| MT900 | - | 250 | 315 | 400 | 500 | 78 | 170 | 44 | 60 | 16 | 180 | 120 | 180 | 900 |

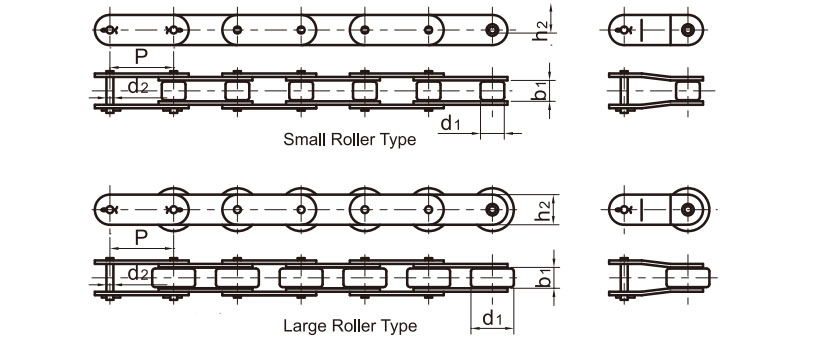

KATINI TAR-ROMBLI TAL-CONVEYOR B'PITCH DOPJU

| GL Numru tal-Katina | Żift | Dijametru tar-romblu | Wisa' ta' ġewwa | Dijametru tal-labra | Fond tal-pjanċa | Saħħa tensjonali aħħarija | Piż għal kull metru | |

| iso | ANSI | P | d1 | b1 | d2 | hi | Q | q |

|

|

| mm | mm | mm | mm | mm | kN | kg/m² |

| Ċ208A | Ċ2040 | 25.40 | 7.92 | 7.85 | 3.98 | 12.07 | 13.90 | 0.50 |

| Ċ208AL | Ċ2042 | 15.88 | 0.84 | |||||

| Ċ208B | A | 25.40 | 8.51 | 7.75 | 4.45 | 11.81 | 17.80 | 0.55 |

| Ċ208BL | A | 15.88 | 0.89 | |||||

| Ċ210A | Ċ2050 | 31.75 | 10.16 | 9.40 | 5.09 | 15.09 | 21.80 | 0.73 |

| Ċ210AL | Ċ2052 | 19.05 | 1.27 | |||||

| Ċ212A | Ċ2060 | 38.10 | 11.91 | H2O2C7 | 5.96 | 18.10 | 31.30 | 1.12 |

| Ċ212AL | Ċ2062 | 22.23 | 1 ^.0 r | 1.61 | ||||

| Ċ212AH | Ċ2060H | 38.10 | 11.91 | 12.57 | 5.96 | 18.10 | 31.30 | 1.44 |

| Ċ212AHL | C2062H | 22.23 | 2.07 | |||||

| Ċ216A | Ċ2080 | 50.80 | 15.88 | 15.75 | 7.94 | 24.13 | 55.60 | 2.08 |

| Ċ216AL | Ċ2082 | 28.58 | 3.12 | |||||

| Ċ216AH | Ċ2080H | 50.80 | 15.88 | 15.75 | 7.94 | 24.13 | 55.60 | 2.54 |

| Ċ216AHL | C2082H | 28.58 | 3.58 | |||||

| Ċ220A | Ċ2100 | 63.50 | 19.05 | 18.90 | 9.54 | 30.17 | 87.00 | 3.01 |

| Ċ220AL | Ċ2102 | 39.67 | 4.83 | |||||

| Ċ220AH | Ċ2100H | 63.50 | 19.05 | 18.90 | 9.54 | 30.17 | 87.00 | 3.56 |

| Ċ220AHL | C2102H | 39.67 | 5.38 | |||||

| Ċ224A | Ċ2120 | 76.20 | 22.23 | 25.22 | 11.11 | 36.20 | 125.00 | 4.66 |

| Ċ224AL | Ċ2122 | 44.45 | 7.66 | |||||

| Ċ224AH | Ċ2120H | 76.20 | 22.23 | 25.22 | 11.11 | 36.20 | 125.00 | 5.26 |

| C224AHL | Ċ2122H | 44.45 | 8.26 | |||||

| Ċ232A | Ċ2160 | 101.60 | 28.58 | 31.75 | 14.29 | 48.26 | 223.00 | 8.15 |

| Ċ232AL | Ċ2162 | 57.15 | 13.00 | |||||

| Ċ232AH | Ċ2160H | 101.60 | 25.58 | 31.75 | 14.29 | 48.26 | 223.00 | 9.06 |

| Ċ232AHL | Ċ2162H | 57.15 | 12.77 | |||||

Il-ktajjen tal-conveyor jintużaw f'varjetà ta' applikazzjonijiet diversi bħas-servizz tal-ikel u l-partijiet tal-karozzi. Storikament, l-industrija tal-karozzi kienet utent ewlieni ta' dan it-tip ta' trasport ta' oġġetti tqal bejn diversi stazzjonijiet fi ħdan maħżen jew faċilità ta' produzzjoni. Is-sistemi robusti tal-conveyor bil-katina jippreżentaw metodu kosteffettiv u affidabbli biex tingħata spinta lill-produttività billi jżommu l-oġġetti 'l bogħod mill-art tal-fabbrika. Il-ktajjen tal-conveyor jiġu f'varjetà ta' daqsijiet, bħal Standard Roller Chain, Double Pitch Roller Chain, Case Conveyor Chain, Stainless Steel Conveyor Chains – C Type, u Nickel Plated ANSI Conveyor Chains.